+86-0559-5290604

FORGING AHEAD,

LINK FIBER TO FUTURE!

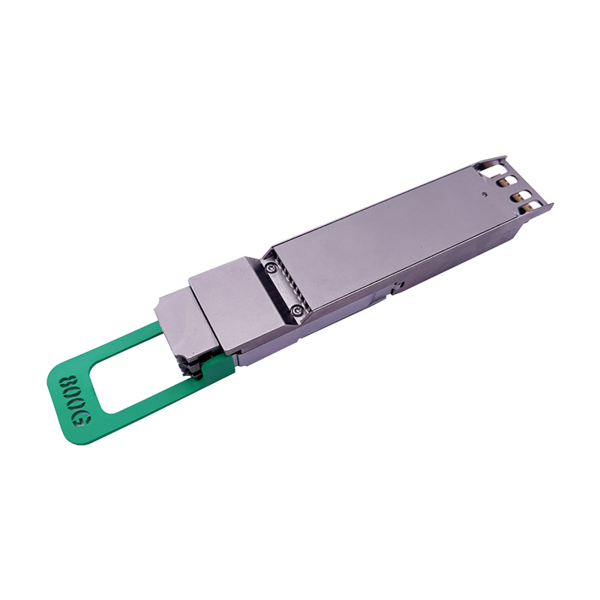

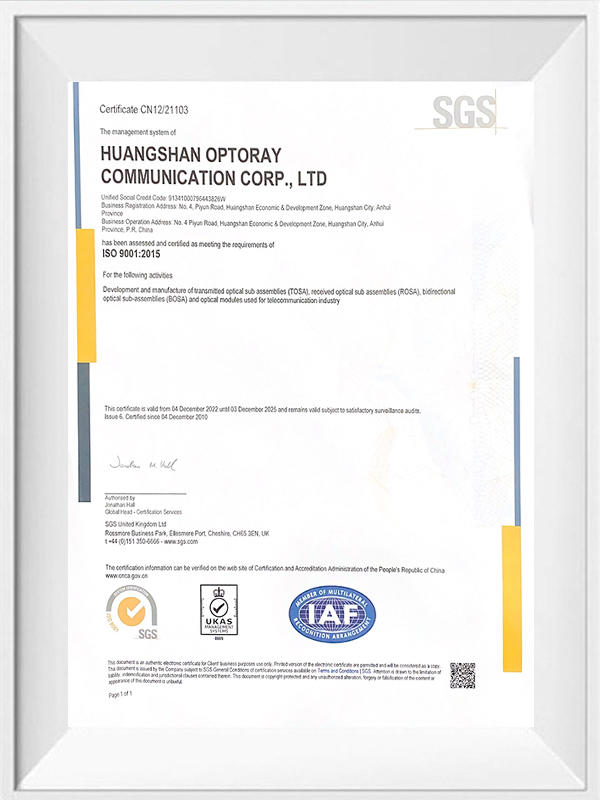

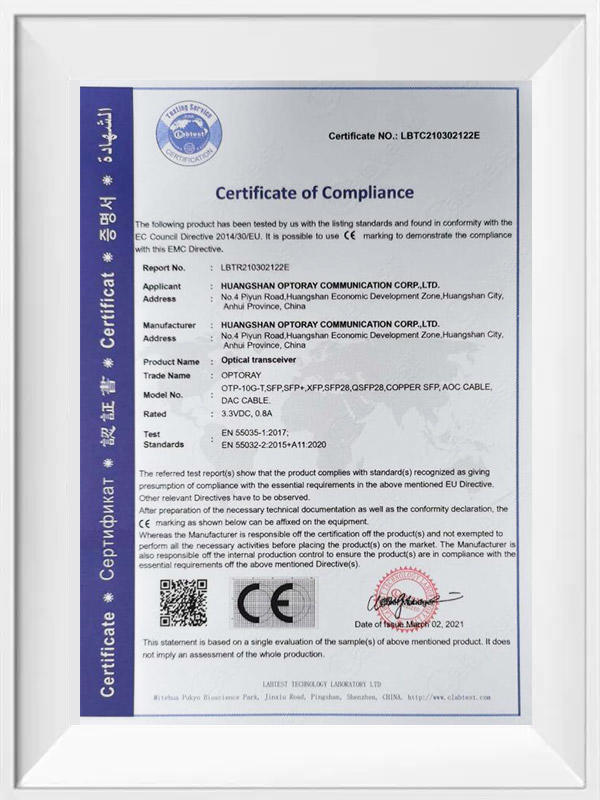

Optoray is China 800G Optical Transceiver Manufacturers and 800G Optical Transceiver Wholesalers. Optoray has a full series of 800G Optical Transceiver and sub-assembly devices from 1Gbps to 400Gbps, which application covers Datacom, Telecom, Video surveillance, and FTTX... And so on. Founded in Huangshan economic development zone, Anhui province in 2007 while the R&D center is in Shenzhen! the phase covers 10,000 square meters. Currently, we already own dozens of related patents and have passed ISO9001:2015 quality system certification and FCC, CE, and RoHS test certification.

Follow company news and information to understand industry trends.

-

QSFP28-100G-ER4: Is it the ultimate solution for data transmission?

QSFP28-100G-ER4: Is it the ultimate solution for data transmission?In the digital age, the speed and reliability of data transmission are crucial to the development of all walks of life. ...

-

Incredibly innovative! Can 10G SFP duplex modules and 10GBASE-SR multi-mode technology change your understanding of network communications?

Incredibly innovative! Can 10G SFP duplex modules and 10GBASE-SR multi-mode technology change your understanding of network communications?In today's era of digitalization and informationization, the demand for network connections continues to grow, especiall...

-

Optical modules: the future of information transmission, are you ready to meet the challenges?

Optical modules: the future of information transmission, are you ready to meet the challenges?With the advent of the digital age, the demand for information transmission speed and capacity is growing day by day. As...

-

SFP module: critical path to network connectivity?

SFP module: critical path to network connectivity?As a key component of network connection, SFP (Small Form-Factor Pluggable) module is widely used in various fields. Fro...

800G Optical Transceiver Industry knowledge

How do 800G optical transceiver suppliers ensure that 800G optical modules have good compatibility and interoperability?

With the rapid development of information technology, the requirements for data transmission speed are also constantly increasing. In this context, as a key component of high-speed data transmission, the performance stability and reliability of 800G optical modules are particularly important. For 800G optical module suppliers, ensuring that products have good compatibility and interoperability is not only a basic requirement to meet market demand, but also the key to improving product competitiveness and winning customer trust.

800G optical transceiver suppliers need to fully consider compatibility and interoperability issues during the product development stage. This includes an in-depth understanding of industry standards and technical specifications to ensure that products are designed to comply with relevant international and domestic standards. At the same time, it is also necessary to conduct sufficient research on the target market to understand the actual needs of different equipment manufacturers and users, so as to achieve the greatest degree of compatibility in product design.

During the production process, suppliers need to strictly control product quality to ensure that every optical module shipped meets the design requirements. This includes the use of high-quality raw materials, advanced production processes and strict quality inspection processes. Through strict quality control, compatibility and interoperability problems caused by product quality issues can be minimized.

In addition to the quality of the product itself, suppliers also need to provide complete after-sales service and technical support. When users encounter compatibility and interoperability issues during use, suppliers can respond quickly and provide effective solutions. This can not only solve users' urgent needs, but also enhance users' trust and satisfaction with the product.

In addition, suppliers can jointly promote technological innovation and progress by establishing close cooperative relationships with partners. By sharing resources and technological achievements, the research and development and promotion of new products can be accelerated, and the technical level and market competitiveness of the entire industry can be improved.

What optimization measures have 800G optical transceiver manufacturers taken in terms of power consumption and heat dissipation of 800G optical modules?

In the rapid development of the communications industry, 800G optical modules are gradually becoming a key force in the field of data transmission with their excellent transmission performance. However, with the improvement of performance, the power consumption and heat dissipation problems caused by optical modules during operation have become increasingly prominent. In order to ensure the stable operation of optical modules and extend their service life, 800G optical transceiver manufacturers have taken a series of optimization measures in terms of power consumption and heat dissipation.

In terms of power consumption, manufacturers reduce the energy consumption of optical modules during operation by optimizing circuit design. Specifically, they use advanced low-power chips and high-efficiency power management technology to reduce unnecessary energy consumption. At the same time, manufacturers have also implemented refined power consumption control for different working modes of optical modules to ensure that the lowest power consumption level is achieved while meeting performance requirements.

In terms of heat dissipation, manufacturers have adopted a variety of technical means to ensure that optical modules can maintain good heat dissipation performance when working. First, they optimized the internal structure of the optical module and improved the heat transfer efficiency through reasonable layout and heat dissipation channel design. Secondly, manufacturers also use efficient heat dissipation materials, such as metal materials with good thermal conductivity and heat pipe technology, to speed up the dissipation of heat. In addition, some manufacturers have also introduced intelligent cooling systems that monitor the temperature changes of optical modules and automatically adjust the speed of cooling fans to achieve precise heat dissipation.

In addition to the above technical means, manufacturers also focus on improving the thermal design capabilities of optical modules as a whole. They comprehensively evaluated and optimized the thermal performance of the optical module through a combination of simulation analysis and experimental verification. At the same time, manufacturers have also strengthened cooperation with equipment manufacturers to jointly formulate and optimize heat dissipation solutions for optical modules to ensure good heat dissipation effects in practical applications.

800G optical transceiver manufacturers have taken a series of optimization measures in terms of power consumption and heat dissipation to ensure the stable operation of the optical module and extend its service life. These measures not only improve the performance and reliability of optical modules, but also provide strong support for the development of the entire communications industry.

English

English русский

русский

+86-186 5596 6697

+86-186 5596 6697