+86-0559-5290604

800G OSFP DAC

-

Parameters

Part No. Length Date Rate AWG Length Tolerance O800-DP0.5M 0.5M 800G 30 +50/-20mm O800-DP1M 1M 800G 30 +70/-25mm O800-DP1.5M 1.5M 800G 26 +70/-30mm O800-DP2M 2M 800G 26 +70/-30mm -

Features & Application

-

Feedback

FORGING AHEAD,

LINK FIBER TO FUTURE!

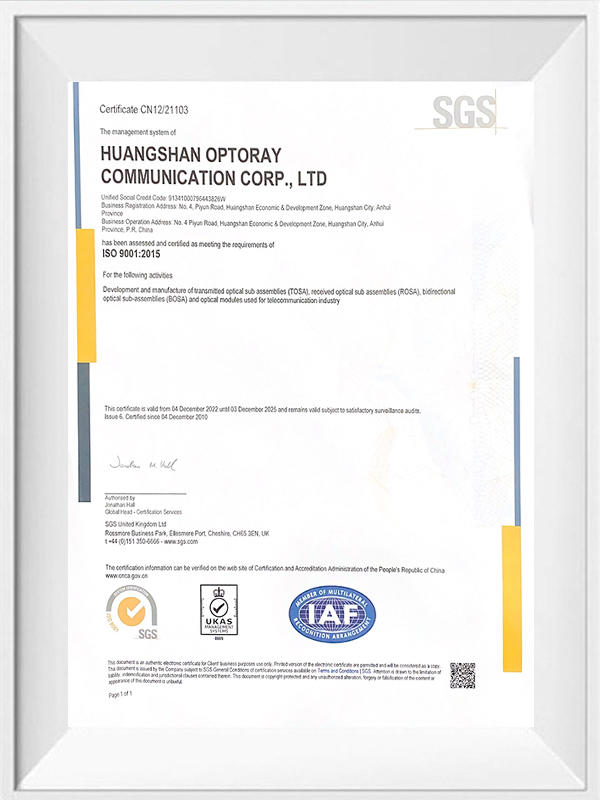

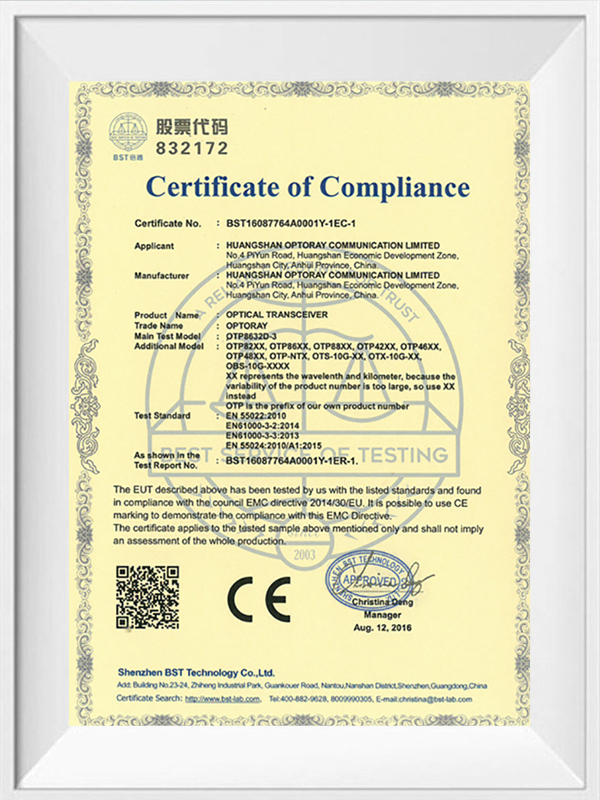

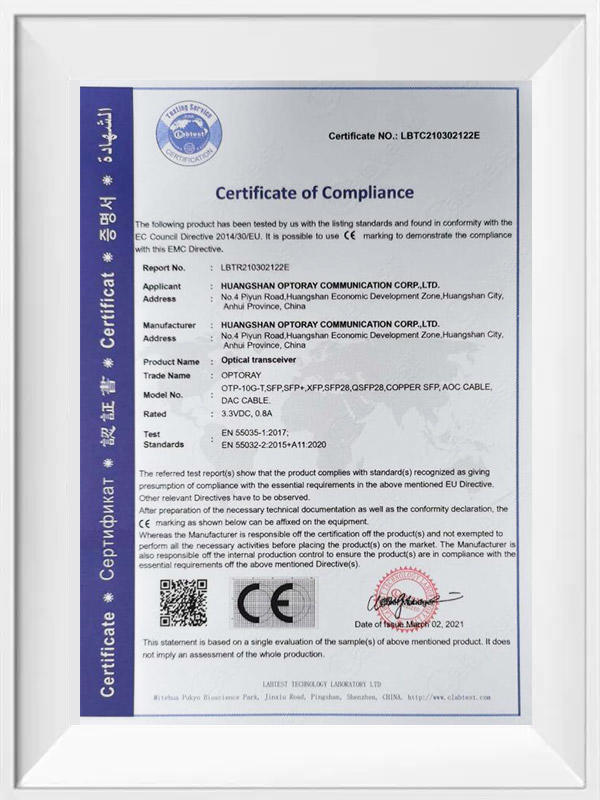

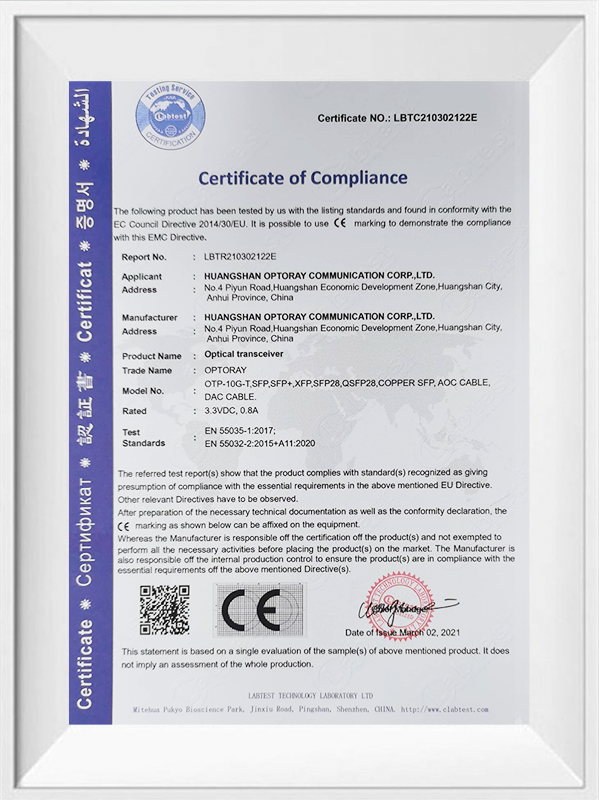

Optoray is China 800G OSFP DAC Optical Transceiver Suppliers. We are professional high-tech enterprise that is engaged in 800G OSFP DAC Optical Transceiver Modules and sub-assembly device research and development, production, and sales; Founded in Huangshan economic development zone, Anhui province in 2007 while the R&D center is in Shenzhen! the phase covers 10,000 square meters. Optoray is a Professional production 800G OSFP DAC Transceiver Company that has a full series of optical transceiver modules and sub-assembly devices from 1Gbps to 400Gbps, which application covers Datacom, Telecom, Video surveillance, and FTTX... And so on. Thanks to our outstanding value in " performance, quality, price, and service" we own many valued customers in China and Overseas such as North America, Korea, India, and Vietnam! Currently, we already own dozens of related patents and have passed ISO9001:2015 quality system certification and FCC, CE, and RoHS test certification.

Follow company news and information to understand industry trends.

-

QSFP28 100G optical module: the best choice for data transmission?

QSFP28 100G optical module: the best choice for data transmission?Driven by today's digital wave, the demand for data centers and network communications continues to expand, and the demand for high-speed, high-bandwidth transmission solutions has...

-

10G SFP Duplex 300m 850nm LC Connector: The Best Choice for Enterprise Networks?

10G SFP Duplex 300m 850nm LC Connector: The Best Choice for Enterprise Networks?In today's digital age, data transfer speeds and network performance are critical to business operations. In the selection of network equipment, the 10G SFP duplex 300m 850nm LC co...

-

Optical transceiver: the door to the communication world, how to turn light into electricity?

Optical transceiver: the door to the communication world, how to turn light into electricity?Optical transceiver is an important part of modern communication networks, especially playing a vital role in optical fiber networks. It is a key device in the optical fiber access...

DAC Optical Transceiver Industry knowledge

How do DAC optical transceiver suppliers ensure the integrity and accuracy of data during the conversion process of DAC optical modules?

With the rapid development of information technology, optical communication technology plays an increasingly important role in the field of data transmission. As a key component in the optical communication system, the DAC optical transceiver (Digital-to-Analog Converter optical module) plays a vital role in the data conversion process. Therefore, DAC optical transceiver suppliers must take a series of measures to ensure the integrity and accuracy of data during the conversion process.

DAC optical transceiver suppliers need to strictly select high-quality raw materials and components. High-quality raw materials are the basis for manufacturing high-quality DAC optical modules, while precise components ensure the stability of data during the conversion process. Suppliers should develop long-term relationships with reputable suppliers and conduct regular quality inspections of raw materials and components to ensure they meet strict performance standards.

Suppliers need to adopt advanced production processes and technologies. Modern optical communication technology has extremely high requirements on the manufacturing process and technology of DAC optical modules. Suppliers should invest substantial resources in research and development and adopt advanced production equipment and technology to ensure the accuracy and consistency of DAC optical modules during the manufacturing process. At the same time, suppliers should also establish a complete quality management system and strictly monitor and control the production process to ensure product quality.

DAC optical transceiver suppliers also need to conduct rigorous testing and verification. After the DAC optical transceiver is manufactured, the supplier should conduct a series of testing and verification work to ensure that its performance meets the standards. These tests include but are not limited to functional testing, performance testing, stability testing, etc. Through these tests, suppliers can discover and repair potential problems in time, thereby ensuring the integrity and accuracy of data during the conversion process of DAC optical modules.

In addition to the above measures, DAC optical transceiver suppliers should also provide complete after-sales service and technical support. During use, customers may encounter various problems or require technical support. Suppliers should establish a professional after-sales service team to respond to customer needs in a timely manner and provide effective solutions. This not only enhances customer trust and satisfaction, but also helps suppliers continuously improve their products and services and increase market competitiveness.

How do DAC optical transceiver manufacturers design the low power consumption characteristics of DAC optical modules?

With the continuous development of communication technology, optical communication modules play an increasingly important role in data transmission. As a key component, the DAC optical transceiver has a balance between performance and power consumption that is particularly critical. The low power consumption feature not only extends the service life of the device and reduces operating costs, but also helps reduce heat generation and improve system stability. Therefore, DAC optical transceiver manufacturers will pay special attention to and optimize its low power consumption characteristics during the design process.

DAC optical transceiver manufacturers will start from the chip design level and adopt low-power chip architecture and technology. They will choose chips with high energy consumption ratio and reduce unnecessary power loss by optimizing the circuit layout and component selection inside the chip. At the same time, manufacturers will also use advanced packaging technology to reduce power consumption between the chip and external circuits.

In circuit design, manufacturers will use a series of energy-saving technologies and strategies. For example, they will use dynamic voltage and frequency scaling technology to adjust the voltage and frequency of the module according to changes in workload to reduce power consumption. In addition, the energy loss during the conversion process will be reduced by optimizing the signal processing algorithm. At the same time, manufacturers will also focus on power management design to ensure the stability and efficiency of power supply and avoid energy waste.

Manufacturers will also consider adopting low-power driver circuit and interface designs. They will choose driver chips with low energy consumption characteristics, optimize the layout and connection methods of interface circuits, and reduce power loss at the interface. These measures not only help reduce the overall power consumption of the DAC optical transceiver, but also improve the overall energy efficiency of the system.

Finally, during the product production and testing stages, manufacturers will conduct strict power consumption tests on DAC optical modules. They will use professional testing equipment and methods to measure the power consumption performance of the module under different working conditions, and make targeted optimizations based on the test results. Through continuous testing and improvement, manufacturers can ensure that DAC optical modules have excellent low-power consumption characteristics in practical applications.

English

English русский

русский